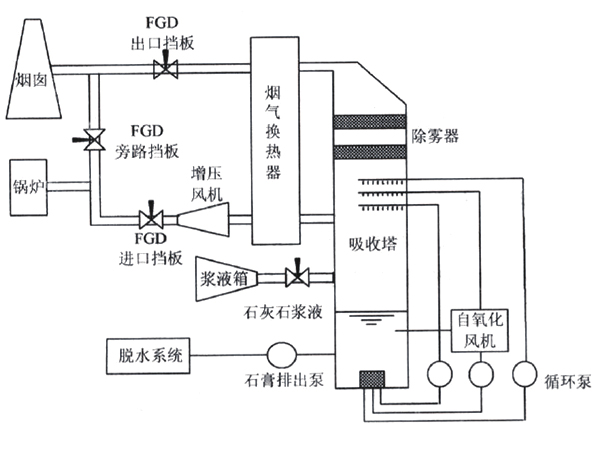

Separated high-efficiency heat pipe GGH low-temperature flue gas heat exchange system

since 2004

since 2004

Striving for excellence, ensuring safety and reliability, scientific management, and continuous improvement

Contact: Zhou Jianyue / Pu Xiaoxian

Mobile: +86-13906172147 / +86-13861845128

Tel: +86-0510-85181448

Fax: +86-0510-85186105

Postal code: 214161

Web: www.fnposuiji.cn

E-mail: wxzysh888@163.com

Add: 21-1 Luou Road, Xituo District, Hudai Industrial Park, Binhu District, Wuxi City